Sintered wire mesh metal filter cloth is a porous metal plate made from multilayer stainless steel wire mesh, and sintered into one metal panel. It is usually consists of 5 layer (or 6-8 layer) mesh: protect mesh layer, filter mesh layer, protection mesh layer, reinforcement mesh layer, and reinforcement mesh layer. With high mechanical strength and wide filter rating ranges, sintered filters are a new fine materials for filtration used in food, beverage, water treatment, dust removing, pharmaceutical, and polymer industry.

The materials of sintered wire mesh commonly is stainless steel 304, SS316,SS316L, but Alloy Steel Hastelloy, Monel, Inconel and other metal or alloy as materials also available according customers filter process requirement. Sintered stainless steel filter is the most widely used type among all the materials due to its excellent chemical stability and long service life.

The protect mesh layer and filter layer are fine stainless steel woven wire mesh, and reinforcement mesh layer can be plain woven, dutch woven type wire or perforated metal sheet.

Plain weave sintered square woven wire mesh has good permeability characteristics and low resistance to flow. It can be designed with any number and combination of square plain weave wire mesh layers to achieve particular flow and filtration characteristics. Its filter rating range is from 1 um to 200 um, and max plate sizes up to 1200 × 1500 mm.

Dutch woven sinter wire mesh plate has evenly spaced openings and steady air permeability to flow, and has very great mechanical strength, commonly used in powder transport, laboratory fluid bed, driers, coolers and other dry solid materials.

Perforated sintered mesh has perforated metal as reinforcement layer support the sintered filter structure. So, it has very high compressive and mechanical strength. Perforated metal sintered filters are well used in oil wells, where fine particles need to be filtered under extremely high pressure conditions.

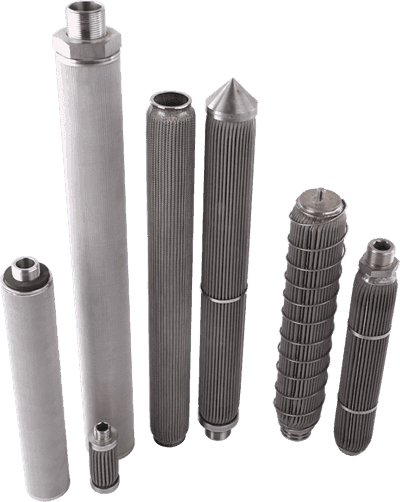

The sintered metal filter panels mentioned above may be formed into filter elements such as filter discs, filter cartridge, filter laminate, and filter tube. Sintered filter elements are made by moulds through high temperature sintering process forming different shape filters such as filter baskets and cone-shape filter, cup filters, cap filters, and filter plate.

Sintered filter disc, available in round, oval, annulus shapes and in split and integral type, can work well in -200°c to 600°c for drying and filtering, filter rate 2-300 microns.

Sintered mesh laminates with the ability to maintain a steady filter rating under high pressure, are easy to clean with a variety of filter cleaning techniques and reuse. It is widely used in water treatment, liquid and gas filtration industry.

Sintered mesh filter cartridges from stainless steel wire cloth with filter rating 1-250 micron for pharmaceuticals, fluidized beds, liquid and gas filtration.

Sintered mesh filter cartridges from stainless steel wire cloth with filter rating1-250 micron for pharmaceuticals, fluidized beds, liquid and gas filtration.

Read more

5 - 7 layers sintered mesh laminates are the fine materials for filtration, and can be welded to filter elements as tube, cylinders, disc and conical shapes.

Read more

Sintered stainless steel powder filter element is widely used in filtration of chemical sector, pharmacy, metallurgy, petroleum and environmental protection.

Read more

Sintered copper powder filter elements are widely used in lubricants, crude oil sand filtration, nitrogen hydrogen filtration, pure oxygen filtration and bubble generator.

Read moreIf you need sintered wire mesh information or quote, please don't hesitate to contact us at info@sinteredfilter.org. We are here to help!

We purchased the sintered wire mesh for our oil and gas filtering, the multi-layers structure supplied high filtering performance, which made our works easy and high efficient.

We purchased the perforated sintered wire mesh in our chemical filtering in the high corrosive environments, after a long term operation, it stills works in high efficiency without any loss or damage.

We purchased the iron-chromium-aluminum fiber felt in the boiler improvement, they performed high dedusting performance under extremely high temperature conditions. It's a surprise.

We purchased the sintered filter disc in our pharmacy working, it had low to 1 μm filtering precision and the assembly was very easy and convenient.