It is well used in oil wells, where fine particles need to be filtered under extremely high pressure conditions.

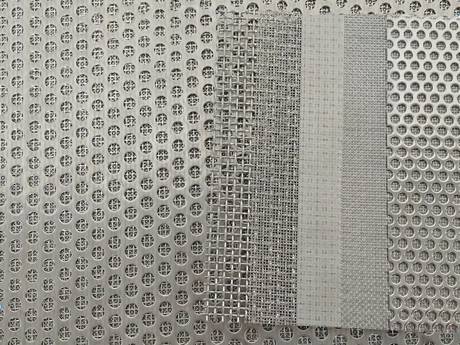

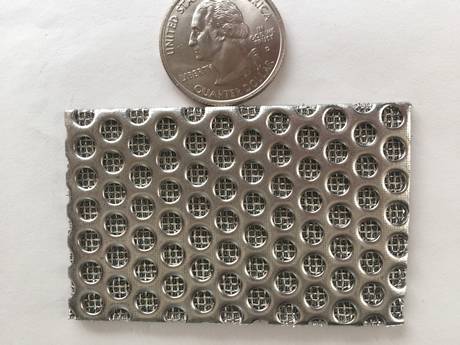

Perforated sintered wire mesh plate is made from several layers of stainless steel woven wire mesh and a perforated metal layer sintering together, usually consisting of five layers (as the left picture shown) - perforated layer, buffer layer, fine mesh, protective layer and filer layer. The above layers are sintered together to form a very study and strong multi-layers filter mesh. The perforated metal as reinforcement layer support the filter structure, which has very high compressive and mechanical strength.

Features: this type sinter mesh filter are resistant corrosion and high temperature, with wide filter rating ranges, having high mechanical strength and the ability to maintain a steady filter rating under high pressure. It is also easy to clean with a variety of filter cleaning techniques, and easy to fabricate, weld, punch, shear or made to filter cartridges and tube.

Perforated metal sintered filter can supply fine filtration, meanwhile protect and preserve the filtration layer. It is well used in oil wells, where fine particles need to be filtered under extremely high pressure conditions. Also used in food, beverage, water treatment, dust removing, pharmaceutical, polymer.

Perforated metal sintered wire mesh specifications:

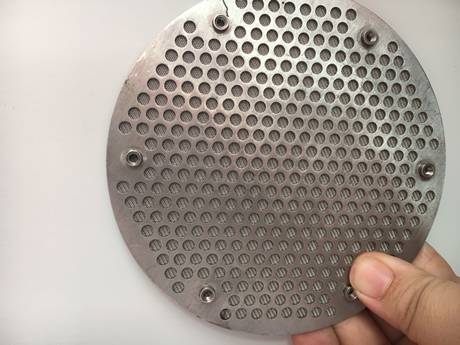

Perforated sintered mesh filter sheets, filter discs, and filter tube in a variety of diameters and lengths are also can be manufactured in our company.

| Model | Filter Rating (um) |

Structure | Thickness (mm) | Weight (kg/m2) | Porosity (%) |

|---|---|---|---|---|---|

| PES4-2.0T | 2 - 200 | 30+Filter layer+30+φ4 × 5P × 1.0T | 2.0 | 6.7 | 57 |

| PES4-2.5T | 2 - 200 | 30+Filter layer+30+φ5 × 7P × 1.5T | 2.5 | 9.8 | 50 |

| PES5-3.0T | 2 - 200 | 60+Filter layer+60+20+φ6 × 8P × 2.0T | 3.0 | 11.8 | 50 |

| PES5-3.5T | 2 - 200 | 20+Filter layer+20+10+φ8 × 10P × 2.0T | 3.5 | 12.6 | 54 |

| PES5-4.0T | 2 - 200 | 20+Filter layer+20+10+φ8 × 10P × 2.5T | 4.0 | 14.2 | 55 |

| PES5-4.3T | 5 - 200 | 20+Filter layer+20+10+φ10 × 13P × 3.0T | 4.3 | 16.9 | 50 |

| PES5-5.3T | 5 - 200 | 20+Filter layer+20+10+φ10 × 13P × 4.0T | 5.3 | 20.6 | 51 |

Note: The porosity is based on 20 u filter layer, the thickness of the punching plate and the structure of the sintered mesh plate can be customized.

Inquiry for Our Product

Boegger Industech Limited

E-mail:

info@sinteredfilter.org

When you contact us, please provide your detail requirements. That will help us give you a valid quotation.

PRODUCTS LIST